Mechanical Engineering faculty and students participate in research programs sponsored by the U.S. Department of Energy, the NASA Glenn Research Center, and industrial partners like Parker-Hannifin, General Electric and Philips Medical Systems, to name a few.

The department maintains excellent instructional and research facilities, including one of the state’s largest anechoic chambers and the unique Center for Rotating Machinery Dynamics and Control. The department maintains state-of-the-art facilities in energy and power systems, control and mechatronics and machine design, including Stirling engines, wind tunnel, machine vision and system monitoring lab, rapid prototyping lab, and rotating machinery dynamics and control lab. The Fenn College of Engineering’s computer network, workstations, PC laboratory, and associated software such as Matlab, AutoCAD, and SolidWorks, are available for research as well as academic activities.

The Thermal Systems Lab

High-Speed Magnetic Bearing Test Stand

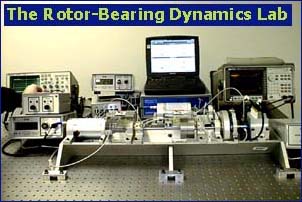

This test stand was custom designed to perform a wide range of experimental research in rotor-bearing dynamics, control and diagnostics. The configuration of the test rig (Fig. 5) provides ability for development and testing of different strategies for controlling rotor vibration, development of control-oriented modeling and design techniques for rotordynamical systems, and study of the new diagnostic techniques based on magnetic bearing actuation and support. The Magnetic Bearing Test Stand consists of:

This test stand was custom designed to perform a wide range of experimental research in rotor-bearing dynamics, control and diagnostics. The configuration of the test rig (Fig. 5) provides ability for development and testing of different strategies for controlling rotor vibration, development of control-oriented modeling and design techniques for rotordynamical systems, and study of the new diagnostic techniques based on magnetic bearing actuation and support. The Magnetic Bearing Test Stand consists of:

- 2 radial magnetic bearings with sensors (12lbf)

- 1 thrust magnetic bearing (27lbf)

- 2 exciter bearings (1/2 of the magnetic bearing capacity)

- 3 different shaft sizes:

- 1/2" dia ´ 12"

- 1/2" dia ´ 25"

- 3/8" dia´ 25"

- brush type motor (15,000RPM, 48VDC)

- 3 movable balance disks: 1" thick and two 1/2" thick

- 4 touchdown bearings (deep groove ball bearings)

- 2 fully digital 5-axis controllers (one for motor and bearings, another one for exciters)

Bently Nevada Rotor Test Rig

The Bently Nevada Rotor Kit is a versatile and compact model of a rotating machine which enable to simulate several categories of lateral shaft vibration by duplicating vibration-producing phenomena found in large rotor-bearing systems, e.g., fluid-film bearing oil whirl/whip, loose rotating parts, mass unbalance, shaft bow, etc. Various vibration characteristics may be observed by changing:

The Bently Nevada Rotor Kit is a versatile and compact model of a rotating machine which enable to simulate several categories of lateral shaft vibration by duplicating vibration-producing phenomena found in large rotor-bearing systems, e.g., fluid-film bearing oil whirl/whip, loose rotating parts, mass unbalance, shaft bow, etc. Various vibration characteristics may be observed by changing:

- rotor speed

- shaft bow

- rotor stiffness

- amount and angle of unbalance

- rotor-bearing relationships

The test rig can also be used to study experimental identification techniques for rotor-bearing systems, and to verify the theoretical modeling predictions.

Rotordynamic Rub Facility

The unique test rig is used to study the high-speed, multi-plane (annular and/or point) rubbing phenomena in rotating machinery and its effect on the rotor dynamic behavior. The test rig include the following:

The unique test rig is used to study the high-speed, multi-plane (annular and/or point) rubbing phenomena in rotating machinery and its effect on the rotor dynamic behavior. The test rig include the following:

- 30in long 3/4" diameter shaft

- two high precision roller element bearings

- 12,000 RPM max speed

- Motor and speed controller (±2% accuracy on RPM, 110VAC 60Hz)

- 2 pair x-y probes (4 probes total)

- 2 annular rub generators (radial) with rub switch mechanisms

- 2 single point rub generators (radial)

- 2 automatic balancers

- 2 rotor mass wheels

- 2 bearing blocks holding Sorbothane washer

- perturbator device

- torque transducer

Stirling Laboratory Research Engine (SLRE)

The SLRE is designed and fabricated as:

The SLRE is designed and fabricated as:

- Horizontally-opposed, two piston, single-acting engine

- Split crankshaft drive mechanism

- Photo-electric sensor is used to sense top dead center and a shaft angle encoder is used to trigger data acquisition

- The engine can be electric motor-driven and, thus, can run as a cooler This facility was completely qualified via a research grant from the Ohio Aerospace Institute (OAI) and utilized by CSU graduate students.

The Anechoic Chamber

The Instrumentaion and Measurements Lab

The Thermoforming Applications Engineering Laboratory (TAEL)

TAEL is a well-equipped center that is available for commercial testing and experimentation. The equipment available includes both production-style apparatus and high precision laboratory devices. With this, the customer may simulate production situations, then gauge the process with state-of-the-art metrology.

TAEL is a well-equipped center that is available for commercial testing and experimentation. The equipment available includes both production-style apparatus and high precision laboratory devices. With this, the customer may simulate production situations, then gauge the process with state-of-the-art metrology.

Equipment and Capabilities

- Single-station production thermoforming machine; MAAC Thermoforming Machine

- A variety of electric and gas-fired heaters

- High pressure gas delivery system

- Exhaust hood that is interlocked with the Combustion system and air makeup unit

- High quality infrared camera for thermal imaging

- Real time analysis capability for up to 32 signals (from thermocouples, the infrared camera, etc.) simultaneously

- Gas flow rate meter

- Electric voltage meter

- Electric current meter

- Gas emission analysis capability

- Spectral emissivity measurement

- Radiant heat characterization with a spectral radiometer

- Design of experiments setup and analysis assistance

CSU Basic Industrial Combustion Workshop

A One-Day Workshop On Combustion Basics 101

A One-Day Workshop On Combustion Basics 101

Partnership with: Dominion/EOG/HTN/NASA/ASGE

Agenda:

- 9:00 Arrive/Welcome

- 9:15 Class Session I (Introduction/Basics/Flame Shape, color, etc/Good Combustion Practice)

- 10:00 Break

- 10:15 Hands-On I

- 11:30 Lunch (Discussion/Feedback)

- 12:30 Class Session II (Available Heat/Good Combustion Results/Thermo & Heat Balance)

- 1:15 Hands-On II

- 2:15 Class Session III (Exercise/Review Hand-On II/Efficient Heating/Activity Summary)

- 3:15 Adjourn